Minimum Order Quantity: 100g

| Attributes | Values |

|---|---|

| Purity | 99.5% |

| Manufacturer Name | Medoja Bio Private Limited |

| CAS NO. | 12167-74-7 |

| Molecular Weight | 502.31 g/mol |

| Grade | Cosmetic |

| Chemical Formula | Ca5(PO4)3OH |

| Particle Size | 30-100nm (Customizable) |

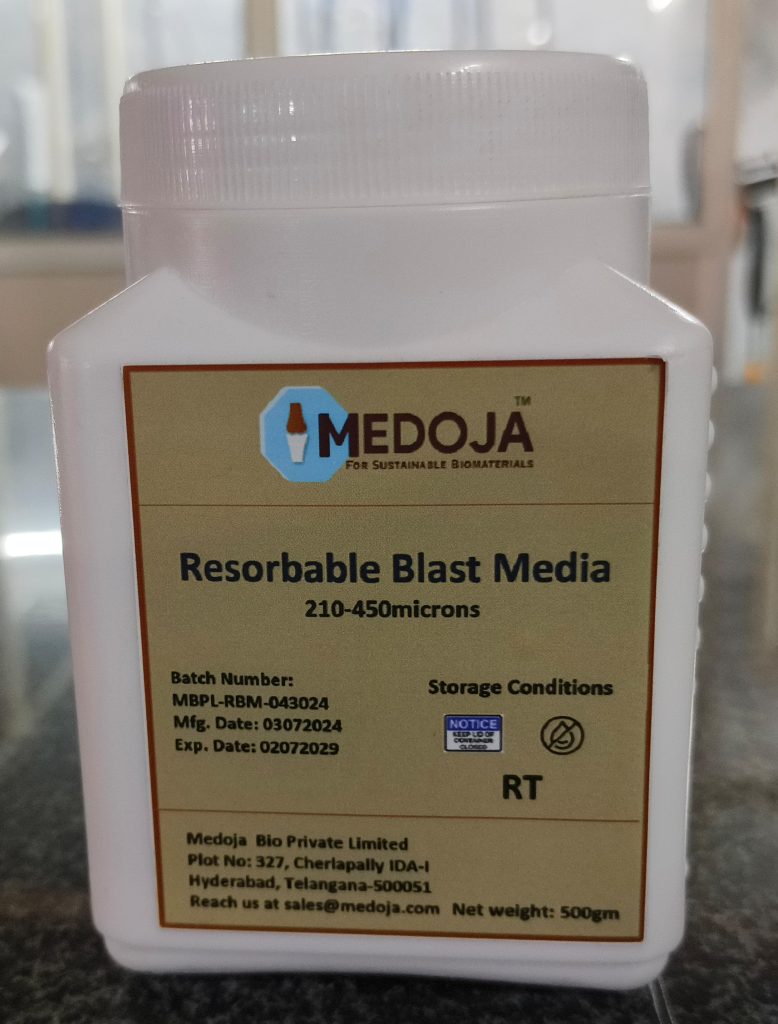

Resorbable Blast Media (RBM) offers a transformative surface treatment solution for dental implants, ensuring minimal residual particles post-treatment. By creating a clean and biologically favorable surface, our RBM supports optimal osteoblast proliferation, leading to faster and more reliable osseointegration. This approach is especially beneficial for immediate implant placements, as it promotes accelerated healing times and reduces the risk of complications.

Thanks to its resorbable properties, our RBM leaves no trace of foreign particles on the implant surface, ensuring a cleaner environment for tissue integration. This helps minimize inflammation and irritation, leading to a more comfortable patient experience. Ideal for contemporary dental implant procedures, our advanced RBM technology supports quicker recovery, stable bone-to-implant interfaces, and higher success rates. By choosing our resorbable blast media, you provide your patients with an innovative solution that not only simplifies the healing process but also promotes long-term implant stability and overall satisfaction.

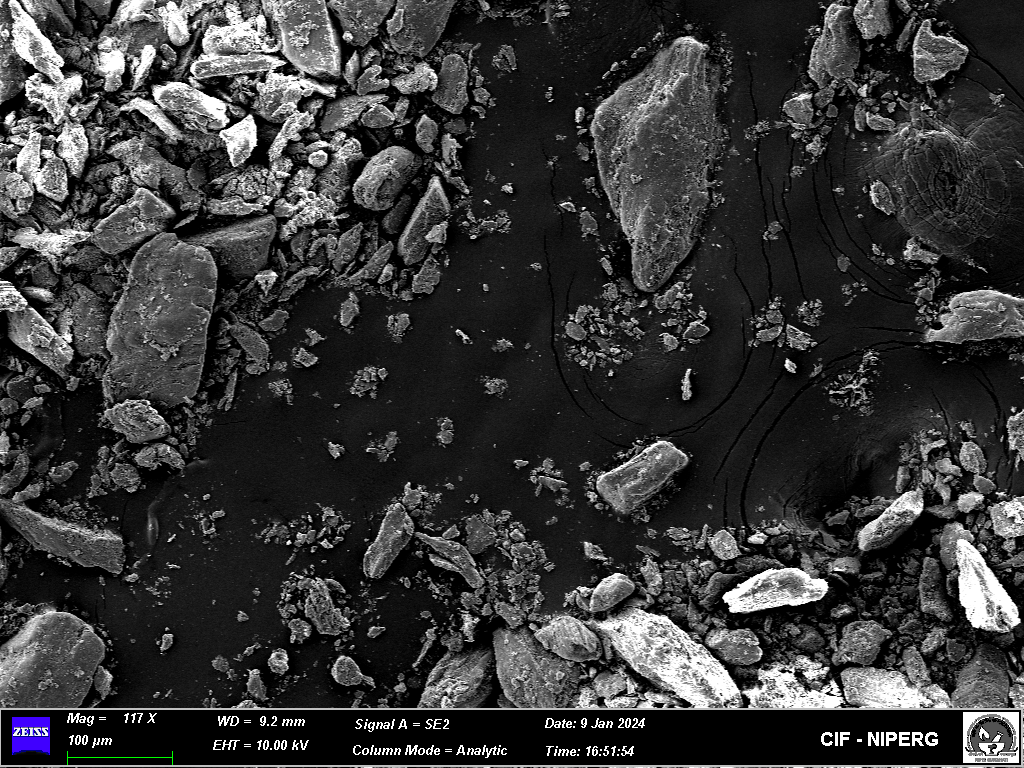

Resorbable Blast Media (RBM) is a surface treatment technique that utilizes biocompatible, resorbable particles to blast the surface of medical implants. This process creates a roughened texture on the implant surface, which is critical in promoting osseointegration—the direct, functional connection between bone and the implant surface.

RBM is predominantly used in the preparation of dental and orthopedic implants, where improved surface roughness leads to:

By using materials like hydroxyapatite powder (HA) and beta-tricalcium phosphate (β-TCP)—which are both biocompatible and resorbable—RBM ensures that any residual blasting media left on the surface will be naturally absorbed by the body. This minimizes the risk of contamination compared to traditional methods using materials such as aluminum oxide.

The implant is blasted with calcium phosphate-based particles at high velocity. After blasting, a thorough cleaning step, often including acid etching, is performed to remove any residual particles. The result is a clean, well-textured implant surface with no biocompatibility concerns.

Dental Implants: RBM-treated implants show improved stability and faster integration with the jawbone.

Orthopedic Implants: Used for bone screws, joint replacements (hip, knee), and spinal devices to enhance bone bonding and reduce loosening.

3D Printed Medical Devices: RBM treatment is employed to clean and roughen the surface of custom 3D-printed implants, ensuring compatibility for bone on-growth.

RBM effectively creates macro-scale roughness, which increases surface area and encourages cell attachment and bone formation. Often, RBM is combined with techniques like acid etching to achieve both micro and macro roughness, optimizing the implant for biological integration.

Only high-purity materials that meet stringent regulatory standards (e.g., ASTM F1185, F1088) are used in RBM. These standards ensure that the materials are safe, effective, and compliant with medical device regulations.

While both techniques aim to improve osseointegration, key differences include:

RBM: Uses resorbable calcium phosphate particles; reduces contamination risk.

SLA: Involves non-resorbable particles followed by acid etching; there is a higher contamination potential if it is not cleaned thoroughly.

Improved osseointegration and BIC

Reduced healing times

Long-term implant stability

Cleaner implant surfaces

Enhanced success rates in difficult implant cases